Topics:

Search for topics or resources

Enter your search below and hit enter or click the search icon.

March 27th, 2024 | 3 min read

In residential remodeling, precision, efficiency, and effective communication are paramount. Every renovation project requires meticulous planning, accurate measurements, and a clear understanding of the space not just from contractors, but from engineers, architects, and designers as well. Traditionally, this process has been challenging, often relying on manual measurements, sketches, and photographs. However, with the advent of cutting-edge laser measurement scanning technology, the way RWS envisions, plans, and executes projects is evolving and this technology not only benefits us but also all our trusted trade partners and clients.

Matterport is a leading provider of 3D capture technology, offering a suite of tools that enable users to create immersive, interactive models of physical spaces. At the heart of Matterport's solution is its state-of-the-art camera, which utilizes depth-sensing technology and advanced algorithms to capture spatial data accurately. The 3D models enable virtual walkthroughs of properties, allowing the viewer to explore every corner of the space from the comfort of their computer or mobile device.

To begin the Matterport scanning process, an RWS-qualified operator places the camera in strategic locations throughout the area to be scanned. Once positioned, the camera rotates automatically covering 360 degrees while capturing a series of high-resolution images from multiple vantage points. The camera emits infrared light patterns (lidar technology), which bounce off surfaces within the space. Sensors on the camera receive this information from the lidar scans, allowing it to calculate distances and create depth maps of the scanned environment.

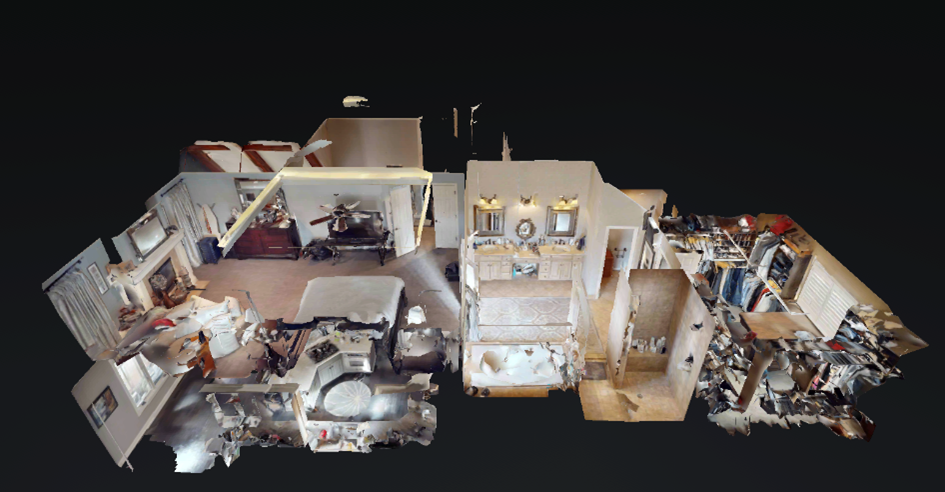

As the operator moves the camera to different vantage points throughout the area, the device continuously captures data, generating a series of interconnected 3D points known as a point cloud. This point cloud is then processed by Matterport's software, which stitches the data together to create a cohesive 3D model of the scanned space, complete with accurate measurements and immersive visuals. The amount of time allocated to scanning a space is directly reflected by the size of the space being renovated. For example, a Matterport scan of a bathroom or kitchen remodel (roughly 60 minutes) will take significantly less time than a full house renovation (up to or exceeding 3.5 hours). Once the scan is complete, the data is uploaded to the Matterport website. They in turn take this information and create a digitized virtual reality replica of your space. That digitized rendering of the space can then be exported into formats such as Revit, AutoCAD, and other architectural platforms. This is the valuable information we can use and share with clients, architects, interior designers, and any trusted trade partner when detailing, planning, and executing a residential remodel.

One of the most significant challenges in remodeling projects is accurately capturing the existing conditions of a space. Advanced 3D technology simplifies this process by creating comprehensive digital replicas of properties. These 3D models provide holistic views of a space, including dimensions, layouts, and structural details. This wealth of information serves as a valuable reference throughout the remodeling process, ensuring that designers, contractors, trusted trade partners, and clients are all on the same page.

Another valuable application of this technology arises during the rough-in phase of remodeling. At this stage, essential mechanical elements such as electrical, plumbing, and HVAC systems are installed and left exposed for city inspection. It's during this critical juncture that we conduct another scan of the area. By doing so, we ensure that once the drywall is installed, we can accurately pinpoint the locations of wires, pipes, and vents within the walls. This approach significantly enhances our efficiency and precision on every project, minimizing the likelihood of errors on the job site. For example, if a homeowner would like to add a sconce to a wall at the end of a project, we can just simply look at the Matterport scan that was conducted at the rough-in stage to see where wires are and how difficult it will be to add. We can give an accurate number and time frame it would take, and the homeowner can make an informed decision on how they would like to move forward.

Whether you're a homeowner looking to breathe new life into your space or a remodeling professional seeking to elevate your craft, embracing tools like the Matterport Camera can help unlock a world of potential.

Remodeling projects often come with their fair share of surprises, from unexpected structural challenges to discrepancies between initial plans and the reality of the space. By leveraging the 3D technology early in the process, many of these potential pitfalls can be identified and addressed proactively. Homeowners, designers, architects, and engineers can make more informed decisions, avoiding costly revisions and delays down the line. Ultimately, this leads to greater satisfaction with the finished product and a smoother remodeling experience overall.

This technology is revolutionizing the field of residential remodeling for trade professionals and clients with a powerful tool for visualization, planning, and execution. With its ability to create accurate precise measurements, immersive virtual walkthroughs, and streamlined project planning, RWS is utilizing 3D technology to set a new standard for excellence in residential remodeling through collaboration with all professionals involved. As technology continues to evolve, integrating innovative solutions like Matterport promises to drive further efficiencies and advancements in the remodeling industry. We invite you to complete this form for more information about having one of our professionals scan your space. For more detailed information on the camera itself, please visit the Matterport website here.

About the Author Ray Stillions is the owner and operator of RWS Enterprises. He is a licensed and insured contractor with a BS degree from Pittsburg State University and has lived in the Kansas City area for over 35 years.

Topics: